Hello! This is GreenPneumatic VTZ, a professional company specializing in vacuum pumps and vacuum equipment.

Today, we’ll take a closer look at the diaphragm vacuum pump.

What is a Diaphragm Vacuum Pump? 🤔

A diaphragm vacuum pump is a special type of equipment used to create a vacuum.

It plays an important role in various industries such as chemical, pharmaceutical, medical, and laboratory applications.

In this article, we’ll explore how diaphragm vacuum pumps work, their advantages, and their main applications.

If you’re interested in vacuum technology, make sure to read until the end! 👍

1. How a Diaphragm Vacuum Pump Works 🛠️

As the name suggests, the diaphragm vacuum pump operates using a thin, flexible membrane called a diaphragm.

Structure:

The diaphragm moves back and forth inside a cylinder, compressing and evacuating air.

It’s typically made from materials with strong chemical resistance, such as PTFE (Polytetrafluoroethylene).

Operating Principle:

The diaphragm moves up and down to create a vacuum.

Air enters through a valve and is expelled as the diaphragm moves.

It operates as an oil-free “dry” pump, making it easy to maintain.

2. Advantages of a Diaphragm Vacuum Pump 🚀

Compared to other vacuum pumps, diaphragm vacuum pumps offer several unique benefits:

Chemical Resistance: Made with corrosion-resistant materials, ideal for handling sensitive substances.

Oil-Free: No oil is required, making it eco-friendly and cost-effective.

Compact and Lightweight: Perfect for labs or workspaces with limited space.

Low Noise: Operates quietly with minimal vibration, creating a comfortable work environment.

3. Main Applications of Diaphragm Vacuum Pumps 🌍

Diaphragm vacuum pumps are essential in many industries:

Chemical & Pharmaceutical: Used for distillation, extraction, and promoting chemical reactions in labs.

Medical: Applied in patient monitoring devices and gas sampling systems.

Environmental Analysis: Ideal for air sampling and gas analysis.

Food & Beverage: Useful in removing air during packaging or vacuum sealing.

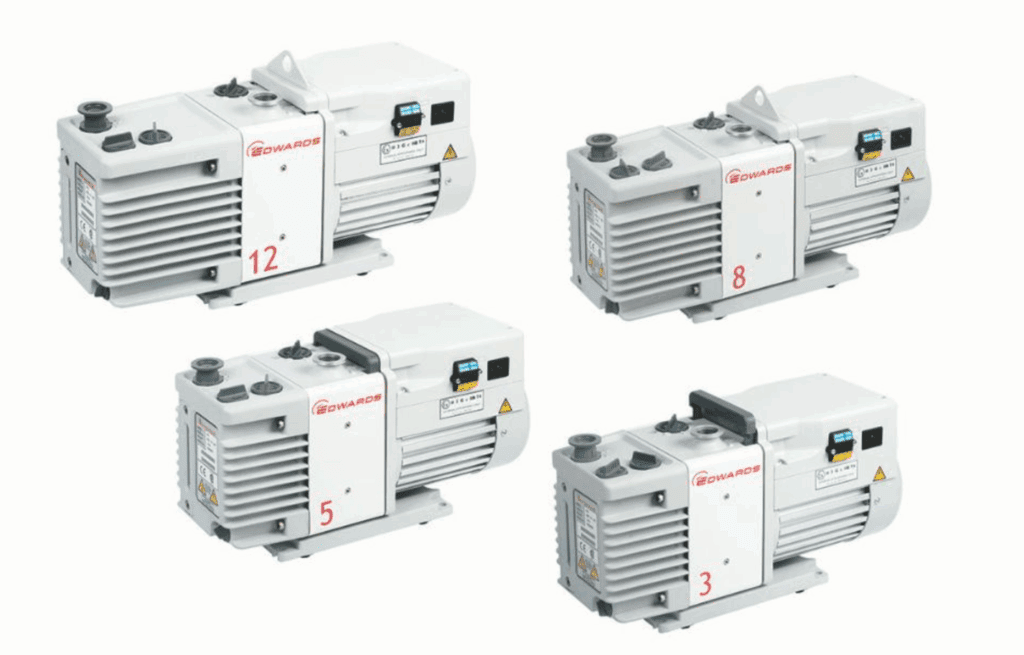

4. Factors to Consider When Selecting a Pump ✅

When choosing a diaphragm vacuum pump, consider the following:

Ultimate Vacuum Level: Check how low the achievable pressure is.

Pump Capacity: Choose a model that matches the required air-handling volume.

Chemical Resistance: Select materials compatible with the substances being handled.

Noise Level: If quiet operation is important, prioritize a low-noise model.

Conclusion 🎯

The diaphragm vacuum pump is a versatile piece of equipment with numerous advantages.

It has proven its usefulness across many industries, including chemical processing, environmental analysis, and medical fields.

Choose the right model for your project or research, and create a more efficient working environment!

Q&A: Frequently Asked Questions about Diaphragm Vacuum Pumps 🤓

Q1. How do I maintain a diaphragm vacuum pump?

A1. Regularly inspect and replace the diaphragm and valves as needed. Since it’s oil-free, maintenance is simple.

Q2. What’s the difference between a regular vacuum pump and a diaphragm type?

A2. Regular pumps often use oil, while diaphragm pumps are oil-free, making them more eco-friendly and cleaner.

Q3. In which industries is it most commonly used?

A3. Widely used in chemical, pharmaceutical, environmental, and medical industries.

Q4. How durable is it?

A4. High-quality models are extremely durable and can operate stably for a long time.

VTZ provides professional services from vacuum pump sales to repair.

If you have any questions about vacuum pumps, feel free to contact us anytime.

We are always here to help ensure your equipment operates at its best.

Thank you!

We always listen to our customers' voices.

Our goal is to move beyond simple product supply to accurately understand and solve our customers' needs.

Contact us anytime, and we will provide the optimal answers and solutions.