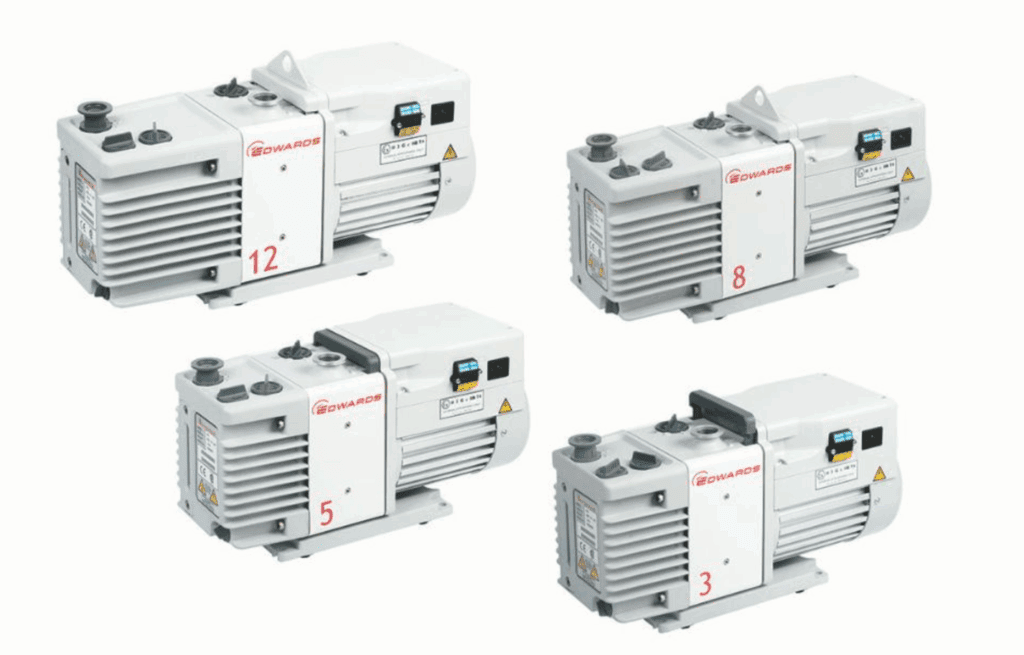

Hello! This is Green Pneumatic VTZ, a professional company specializing in vacuum pumps and vacuum equipment.

Today, we’ll take a look at how to properly maintain oil-sealed vacuum pumps.

💡 Oil-Sealed Vacuum Pump Maintenance Guide

Oil-sealed vacuum pumps are essential components used across various industrial fields.

To ensure optimal performance, regular maintenance is absolutely necessary.

This guide explains in detail how to properly manage your pump to extend its service life and maintain peak performance.

Follow the steps below for reliable operation! 👇

1️⃣ Check the Proper Oil Level

✅ Why is maintaining the correct oil level important?

Oil is the lifeblood of an oil-sealed vacuum pump.

If the oil level is too low or too high, several problems can occur:

Low oil: Reduced vacuum performance, overheating, and even serious equipment damage.

Excessive oil: Back pressure in the exhaust section, vapor emission, and in severe cases, vane breakage.

🛠️ Tips for maintaining the proper oil level

Check the oil level using the oil sight glass.

Maintain the level at the middle of the sight glass.

Since oil level decreases slightly during operation, it’s recommended to fill up to about 3/4 of the sight glass before startup.

2️⃣ Oil Replacement Interval

💧 Why should you change the oil regularly?

Over time, oil becomes contaminated with impurities and loses its viscosity.

Using contaminated oil can reduce vacuum efficiency and damage internal components.

Therefore, regular oil changes are essential.

🕒 Recommended replacement interval

Standard use: Every 1,000 operating hours (assuming 10 hours per day).

Frequency may vary depending on the environment:

If the pump operates above 87°C, replace oil more frequently.

If the oil turns milky, it means moisture has mixed in — replace immediately.

⚠️ Problems caused by moisture-contaminated oil

Lower vacuum performance

Internal corrosion

Vane wear

💡 Tip: Regularly check for contamination to ensure safe and efficient operation.

3️⃣ Choosing the Right Oil

It’s crucial to use oil that matches your vacuum pump’s specifications.

Always follow the manufacturer’s recommendation for best performance.

Suggested viscosity grades:

Motor under 3 kW: Use oil with viscosity ISO VG 68 or lower

Motor 3–10 kW: Use ISO VG 100 oil

Motor above 10 kW: Use ISO VG 150 oil

⚠️ Using the wrong oil can reduce vacuum efficiency and overload the pump — choose carefully!

4️⃣ Maintain the Inlet (Suction) Filter

🤔 Why is the inlet filter important?

If the inlet filter becomes clogged with dust or debris, the exhaust performance decreases and the pump may overheat.

🔄 Cleaning and replacement schedule

Replace every 2,000 operating hours.

Depending on your environment, clean the filter periodically.

A clean inlet filter helps extend pump life and maintain efficiency.

5️⃣ Maintain the Exhaust Filter

🔧 Function of the exhaust filter

The exhaust filter removes oil mist and impurities from the exhaust gas.

When clogged, it can cause back pressure, leading to overheating and pump failure.

🛠️ Replacement timing

Ideally, replace the exhaust filter when changing the inlet filter.

In dusty or contaminated environments, shorten the replacement interval.

🎯 Conclusion

Oil level: Always maintain at the proper level

Oil replacement: Change oil according to operation time and contamination level

Filter maintenance: Regularly inspect and replace inlet and exhaust filters

Routine inspection and maintenance are the keys to sustaining your vacuum pump’s performance.

Proper care will extend equipment life and prevent unexpected breakdowns.

❓ Frequently Asked Questions (Q&A)

Q1. Do I have to use specialized vacuum pump oil?

A: Yes. Using the recommended oil is essential. Ordinary oil may have improper viscosity and damage the pump.

Q2. When should I shorten the oil change interval?

A: If the pump operates at high temperatures or in humid environments, replace oil more frequently.

Q3. Can I just clean the filters instead of replacing them?

A: Light dust can be cleaned, but if the filter is heavily contaminated, replacement is recommended.

Q4. What should I do if the pump temperature rises too high?

A: Stop operation immediately and check the oil level and filter condition.

Ignoring overheating may cause serious damage.

VTZ provides professional services for everything from vacuum pump sales to repair.

If you have any questions regarding vacuum pumps or vacuum systems, feel free to contact us anytime.

We are committed to supporting your equipment’s optimal performance.

This article was written by VTZ, a professional vacuum pump and equipment company.

For assistance or inquiries related to vacuum systems, please contact us below — we’ll be happy to help.

Thank you! 🙏

We always listen to our customers' voices.

Our goal is to move beyond simple product supply to accurately understand and solve our customers' needs.

Contact us anytime, and we will provide the optimal answers and solutions.