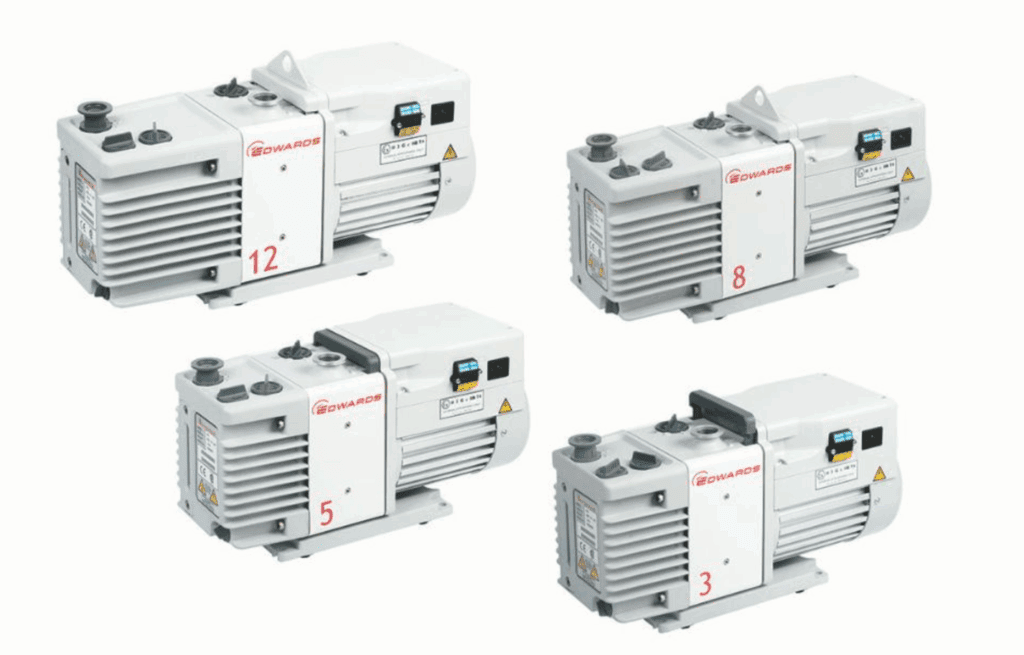

Today, let’s take a closer look at one of the most widely used vacuum pumps in industrial fields — the Rotary Vane Vacuum Pump.

With its simple structure and outstanding reliability, this pump is essential in industries like semiconductors, pharmaceuticals, food, and automotive. 😊

⚙️ Structure and Working Principle

The core components of a rotary vane pump are:

- A rotor placed eccentrically inside a cylindrical housing

- Multiple vanes (blades) attached to the rotor

Here’s how it works:

1️⃣ Suction – As the rotor spins, gas enters the space between the vanes and the housing.

2️⃣ Compression – The chamber volume decreases as the rotor rotates, compressing the gas.

3️⃣ Exhaust – The compressed gas is discharged through the outlet, while a valve prevents backflow.

For a visual explanation, check this short video 🎥

💡 Advantages of Rotary Vane Vacuum Pumps

✅ Long lifespan — often over 20 years of stable operation

✅ Suitable for a wide range of vacuum levels (low to medium vacuum)

✅ Can achieve vacuum levels up to 1×10³ Torr

✅ Compact, cost-effective, and easy to maintain

Thanks to these strengths, the rotary vane pump remains one of the most versatile and trusted vacuum pumps today. 🌟

⚠️ Disadvantages of Rotary Vane Vacuum Pumps

🔸 Oil-lubricated types require regular oil changes

(Though modern dry models eliminate this need.)

🔸 There’s a risk of oil contamination, so filters or traps may be needed for clean processes.

🔸 Exhaust gases are emitted, and oil can freeze in winter, stopping operation.

🔸 Routine maintenance and inspection are essential — involving both time and cost.

Still, with proper care, this pump delivers reliable performance for many years. 🧰

🏭 Applications of Rotary Vane Vacuum Pumps

Rotary vane pumps are used across a wide variety of industries 👇

🔹 Semiconductor & Electronics – Wafer manufacturing, thin-film deposition, packaging

🔹 Research & Laboratories – Mass spectrometers, electron microscopes, spectrometers

🔹 Medical & Pharmaceutical – Freeze dryers, sterilizers, medical device manufacturing

🔹 Food Industry – Vacuum packaging, drying processes

🔹 Automotive – Hydraulic brakes, fuel system testing

🔹 Chemical Industry – Distillation, solvent recovery

🔹 Aerospace – Altitude simulation, space environment testing

🔹 Metal Processing – Vacuum heat treatment, casting

🔹 Environmental Technology – Soil gas extraction, sampling

🔹 Energy Sector – Transformer oil purification, vacuum-insulated switchgear

Typically, rotary vane pumps can achieve vacuums below 10⁻³ mbar and are often used as backing pumps for high-vacuum systems.

🔍 In Conclusion

Rotary vane vacuum pumps combine reliability, affordability, and efficiency — making them an excellent choice for most industrial applications.

With proper maintenance, they can last for decades and deliver consistent performance.

If you have questions about vacuum systems or want to find the best pump for your process, feel free to contact VTZ Vacuum Solutions.

We’re always happy to help! 😊

We always listen to our customers' voices.

Our goal is to move beyond simple product supply to accurately understand and solve our customers' needs.

Contact us anytime, and we will provide the optimal answers and solutions.