Today, let me introduce the vacuum pump used inside high-pressure steam sterilizers. If you work with autoclaves or sterilization systems, the durability of the pump is one of the most important factors you’ll ever consider.😊

🛠️ Why Vacuum Pumps Are Essential in Steam Sterilizers

During sterilization, the chamber must reach deep vacuum levels quickly and consistently to ensure proper steam penetration. Especially in a 50-liter chamber autoclave like the one from Company A, stable vacuum control is crucial for cycle quality.

🔥 Extreme Temperature Resistance Is a Must

Steam sterilizers reach temperatures around 135°C, and hot vapor often enters the pump. Standard pumps degrade quickly in these conditions, which is why durability becomes a top priority when selecting a vacuum pump.

🧪 The Advantage of Teflon Coating

K-One Tech’s piston vacuum pump uses a fully Teflon-coated internal structure. Teflon resists high heat and moisture, significantly reducing wear and ensuring stable performance even in harsh steam environments. When I tested it, it was clear that the pump could withstand prolonged exposure to hot vapor without performance loss.

🔧 Spring-Supported Structure for Reduced Vibration

One thing I personally appreciated was how quiet the pump operated. Thanks to its spring-supported motor design, vibration was almost nonexistent. Many pumps begin to shake or rumble after hours of use, but this one remained smooth and quiet.

🧰 Compatible With Steam, EO Gas, and Plasma Sterilizers

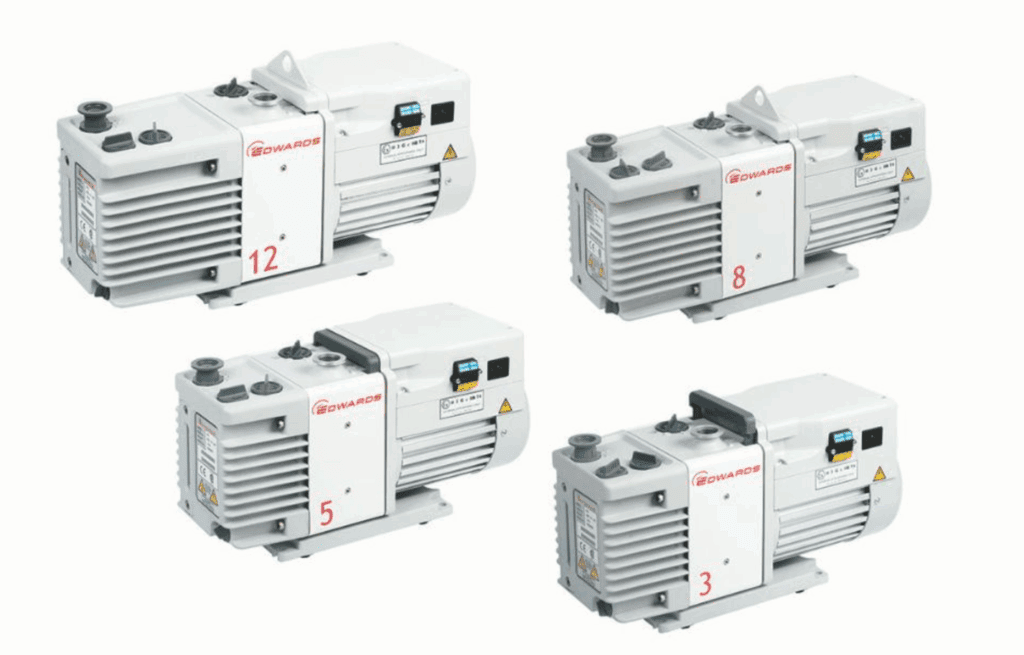

The pump lineup is optimized not only for steam autoclaves but also EO Gas and plasma sterilizers. Since each sterilization method requires different vacuum conditions, having models tailored to each system gives users great flexibility.

📊 Stable and Consistent Performance

What stood out the most was the pump’s consistency. In sterilization, even a minor vacuum failure can lead to a failed cycle. Seeing the pump repeatedly maintain accurate vacuum levels gave me a lot of confidence in its reliability.

🎯 Key Strengths of K-One Tech Vacuum Pumps

– Excellent durability under high-temperature steam

– Low vibration design

– Compatibility with multiple sterilizer types

– Easy maintenance

🎤 FAQ

Q1. Is Teflon coating necessary for steam sterilizers?

A. Yes, it greatly improves durability against hot vapor.

Q2. Can it be used for EO Gas sterilizers?

A. Yes, there are dedicated models available.

Q3. Why is reduced vibration important?

A. It protects nearby equipment, reduces noise, and extends machine life.

Q4. Is maintenance difficult?

A. Not at all—its internal structure is simple and durable.

Q5. Is it suitable for plasma sterilizers?

A. Yes, optimized models are available.

We always listen to our customers' voices.

Our goal is to move beyond simple product supply to accurately understand and solve our customers' needs.

Contact us anytime, and we will provide the optimal answers and solutions.